Leni Acrylic, leka uila PMMA.

Hoʻolauna lens:

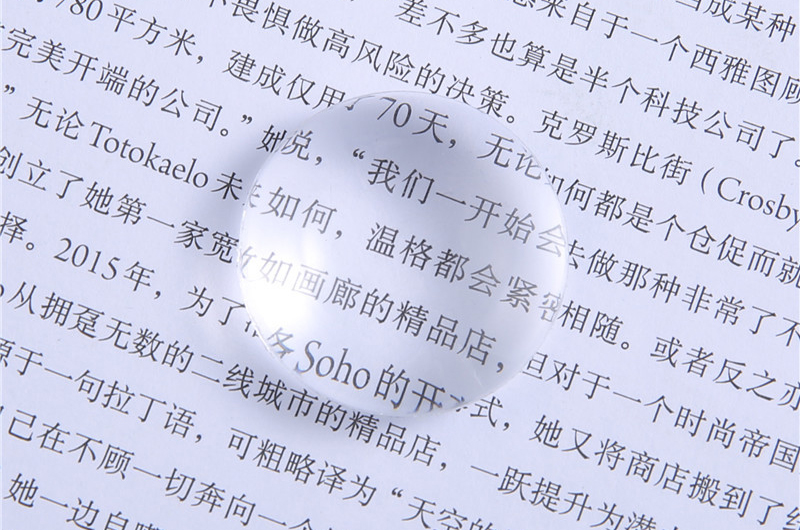

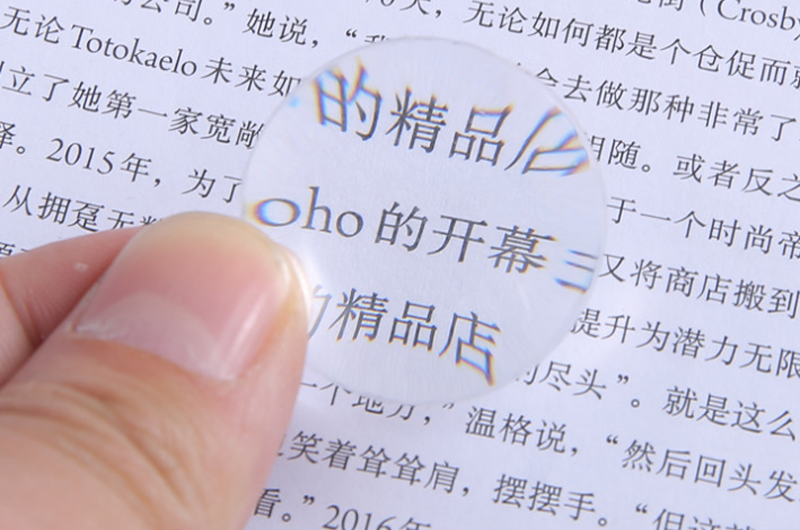

ʻO ka papa kumu o ka lens acrylic i hana ʻia me ka PMMA, ʻo ia hoʻi ka mea i kapa ʻia ka lens acrylic pressed e ka poʻe ma Hong Kong a me Taiwan.ʻO ka lens Acrylic e pili ana i ka pā acrylic extruded.I mea e hoʻokō ai i ka optical grade electroplating, e hoʻokumu ka papa kumu i ka hopena aniani ma hope o ka uhi ʻana i ka vacuum.Hoʻohana ʻia ka lens plastik e hoʻololi i ka lens aniani, nona nā pōmaikaʻi o ke kaumaha māmā, ʻaʻole maʻalahi e wāwahi, hoʻoheheʻe ʻia a me ka hana ʻana, maʻalahi ke kala a pēlā aku, Ke piʻi nei ka manawa hoʻomohala i kēlā me kēia lā, a ua lilo ia i ʻano ʻenehana. i ka hana lens.Hiki ke hana maʻamau i nā pā palaka i: aniani ʻaoʻao hoʻokahi, aniani ʻaoʻao ʻelua, aniani aniani, aniani pepa, hapalua lens, etc. hiki ke hana ʻia e like me nā koi like ʻole.No ka laʻana, hiki ke ʻike ʻia ka pale o ke kelepona paʻalima a me ka TV i kēlā me kēia lā.

Nā hiʻohiʻona lens:

He kūpono ka Acrylic no ka hana lua, e like me ka machining, thermoplastic molding, blow molding, blister, solvent bonding, thermal printing, screen printing and vacuum electroplating.Ma hope o ka kūleʻa, ʻo ia ka mea a mākou i kapa ai he lens acrylic.

Hoʻopili ʻia ka pā aniani e ka methyl methacrylate monomer (MMA), ʻo ia hoʻi ka polymethylmethacrylate (PMMA) pā plexiglass, ʻo ia kahi ʻano plexiglass i hana ʻia e ka hana kūikawā.Loaʻa iā ia ka inoa o "plastic Queen".ʻO ka noiʻi a me ka hoʻomohala ʻana o ka acrylic he mōʻaukala ʻoi aku ma mua o 100 mau makahiki.

Hoʻohana lens:

Loaʻa i ka Acrylic nā mea maikaʻi o ka paona māmā, ke kumu kūʻai haʻahaʻa a me ka hoʻoheheʻe maʻalahi.ʻO kāna mau hana hoʻoheheʻe ʻana e pili ana i ka hoʻolei ʻana, ka hoʻoheheʻe ʻana, ka mīkini, ka thermoforming acrylic, a me nā mea ʻē aʻe.No laila, hoʻohana nui ʻia i nā ʻāpana mea kani, nā kukui kaʻa, nā lens optical, nā paipu aniani a pēlā aku.

ʻO Acrylic ka mea hou maikaʻi loa e hana i nā mea maʻemaʻe ma hope o nā seramika.Ke hoʻohālikelike ʻia me nā mea seramika maʻamau, ʻaʻole wale ka acrylic i ka ʻōlinolino kiʻekiʻe ʻole, akā loaʻa pū kekahi i kēia mau mea maikaʻi: ʻo ka paʻakikī maikaʻi a ʻaʻole maʻalahi e hōʻino;ʻO ka hoʻihoʻi ikaika, ʻoiai ʻo ka huʻa palupalu i ʻū ʻia i loko o ka toothpaste hiki ke holoi i nā mea maʻemaʻe hou.He palupalu ke kino, a ʻaʻohe manaʻo ʻino iwi i ka hoʻoilo;Hiki i nā kala ʻālohilohi ke hoʻokō i ka ʻimi pākahi o nā ʻono like ʻole.ʻO ke kīʻaha papaʻaina, ka ʻauʻau ʻauʻau a me ka lua i hana ʻia me ka acrylic ʻaʻole nani wale i ke ʻano, lōʻihi, akā pili pū kekahi.Ua aneane like kona laina kukuna me ko na iwi kanaka.Ua ʻike mua ʻia nā mea hoʻomaʻemaʻe Acrylic ma ʻAmelika Hui Pū ʻIa a ʻoi aku ka nui ma mua o 70% o ka mākeke honua holoʻokoʻa.Ma muli o ka paʻakikī a me ke kumukūʻai kiʻekiʻe o ka hana acrylic, nui nā mea kūʻai haʻahaʻa haʻahaʻa i ka mākeke.ʻO kēia mau mea pani, ʻike ʻia hoʻi ʻo "acrylic", he papa lāʻau maʻamau maʻamau a i ʻole ka papa hoʻohui (ʻike ʻia ʻo ka papa sandwich).Hoʻolei ʻia ka papa lāʻau maʻamau me ka plexiglass maʻamau a me ka puaʻa.He haʻahaʻa a maʻalahi kona paʻakikī o ka ʻili.ʻAʻole maikaʻi ka hopena polishing ma hope o ka poli ʻana me ke one maikaʻi.ʻO ka papa hoʻohui ʻia he ʻāpana lahilahi wale nō o ka acrylic ma ka ʻili a me ka plastik ABS ma waenakonu.He maʻalahi ke delaminate ma muli o ka mana o ka hoʻonui ʻana i ka wela a me ka hoʻohaʻahaʻa anu i ka hoʻohana.Hiki ke ʻike ʻia ka acrylic ʻoiaʻiʻo a me ka hoʻopunipuni mai ka ʻokoʻa ʻokoʻa o ka waihoʻoluʻu a me ka hopena polishing o ka ʻāpana pā.1 Hoʻolālā hoʻolālā: puka makani, puka kani a me ka puka makani, uhi kukui, hale kelepona, aniani kala hoʻonani, etc. No ka hoʻolaha ʻana: pahu kukui, papa hōʻailona, papa hōʻailona, rack hōʻikeʻike, etc. 4 No ka lāʻau lapaʻau: pēpē incubator, nā mea hana lapaʻau like ʻole, nā ʻatikala kīwila: nā mea hana lima, nā aniani hoʻonaninani, nā pale, nā aquarium, nā aniani pāʻani, etc. mea hōʻike manaʻo, mea hōʻike manaʻo acrylic, etc.

Nā ʻano hana:

1. Aia i loko o ka Acrylic ka methyl ʻaoʻao polar, nona ka hygroscopicity.ʻO ka hoʻopili wai ʻana he 0.3% - 0.4%.Pono ia he papa acrylic ma mua o ka hana ʻana

Pono e maloʻo ma lalo o ke kūlana o 80 ℃ - 85 ℃ no 4-5h.2. Loaʻa i ka Acrylic nā hiʻohiʻona wai non-Newtonian maikaʻi a maopopo i ka pae wela o ka hana ʻana.E emi nui ana ka viscosity hehee me ka pi'i 'ana o ka shear rate, a 'o ka melt viscosity ka mea ma'alahi loa i ka ho'ololi 'ana o ka mahana.No laila, no ka hana ʻana o ka polymethylmethacrylate, hoʻonui i ke kaomi hoʻoheheʻe ʻana a me ka mahana hiki ke hōʻemi nui i ka viscosity heheʻe a loaʻa ka wai maikaʻi.3. ʻO ka mahana e hoʻomaka ai ke kahe ʻana o ka acrylic ma kahi o 160 ℃, a ʻo ka mahana i hoʻomaka ai e decompose ʻoi aku ka kiʻekiʻe ma mua o 270 ℃, me kahi ākea ākea o ka wela.4. He kiʻekiʻe ka viscosity o ka hoʻoheheʻe acrylic, wikiwiki ka wikiwiki, a maʻalahi nā huahana e hana i ke koʻikoʻi o loko.No laila, hoʻomalu pono ʻia nā kūlana kaʻina i ka wā o ka hoʻoheheʻe ʻana, a pono pū nā huahana ma hope o ka mālama ʻana ma hope o ka hoʻoheheʻe ʻana.5. ʻO Acrylic kahi polymer amorphous me ka liʻiliʻi liʻiliʻi a me kona ʻano like ʻole, ma kahi o 0.5% - 0.8%, kahi kūpono i ka hana ʻana i nā ʻāpana plastik me ka pololei kiʻekiʻe.6. He maikaʻi loa ka hana ʻoki ʻana i ka Acrylic, a hiki ke maʻalahi i ka mīkini ʻana i kāna ʻikepili i nā ʻano nui i makemake ʻia.

ʻenehana hana:

Hiki i ka Acrylic ke hoʻohana i ka hoʻolei ʻana, ka hoʻoheheʻe ʻana, extrusion, thermoforming, laser engraving, laser cutting a me nā kaʻina hana ʻē aʻe.

Hoʻoheheʻe ʻia

Hoʻohana ʻia ka hoʻoheheʻe ʻana e hana i nā profiles e like me nā pā plexiglass a me nā kaola, ʻo ia hoʻi, hoʻokumu ʻia nā profiles e ka polymerization nui.Pono nā huahana hoʻolei ma hope o ka mālama ʻana.ʻO nā kūlana ma hope o ka mālama ʻana he mālama wela no 2h ma 60 ℃ a me ka mālama wela no 2h ma 120 ℃

Hoʻoheheʻe ʻia

Hoʻohana ʻia ka hoʻoheheʻe ʻana i ka mea granular i hoʻomākaukau ʻia e ka polymerization suspension, a lawe ʻia ka hoʻoheheʻe ʻia ma ka plunger maʻamau a i ʻole ka mīkini hoʻoheheʻe ʻia.Hōʻike ka papa 1 i nā kūlana kaʻina hana maʻamau o ka polymethylmethacrylate injection molding.Kaʻina kaʻina hana hoʻoheheʻe ʻia ka mīkini hoʻoheheʻe plunger i hoʻoheheʻe ʻia i ka pahu pahu ℃ wela hope 180-200 180-200 waena 190-230 mua 180-210 210-240 wela nozzle ℃ 180-210 210-240 wela wela 40-80 ℃ kaomi MPa 80-120 80-130 paʻa puʻe MPa 40-60 40-60 screw speed rp.m-1 20-30 injection huahana pono hoʻi ma hope o ka mālama ʻana e hoʻopau i ke kaumaha o loko, Hoʻokō ʻia ka mālama ʻana i kahi 70-80 ℃ umu hoʻomaloʻo kaapuni wela.ʻO ka manawa lapaʻau o ka pahu acrylic ma kahi o 4H ma muli o ka mānoanoa o ka huahana.

Thermoforming

ʻO ka Thermoforming ka hana o ka hana ʻana i ka pā plexiglass a i ʻole ka lau i nā huahana o nā ʻano nui a me nā ʻano like ʻole.Hoʻopili ʻia ka ʻoki hakahaka i loko o ka nui i makemake ʻia ma ke ʻano o ka mold, hoʻomehana ʻia e hoʻoluliluli ʻia, a laila kaomi ʻia e hoʻokokoke i ka ʻili i loaʻa ke ʻano like me ka ʻili.Ma hope o ka hoʻoluʻu ʻana a me ka hana ʻana, ʻoki ʻia ka lihi e loaʻa ai ka huahana.Hiki ke hoʻohana ʻia ke ʻano o ka huki ʻana a i ʻole ke kaomi pololei ʻana o ka punch me ka profile no ka kaomi ʻana.Hiki i ka thermoforming wela ke kuhikuhi i ka wela wela i mana'o 'ia ma ka Papa 3. I ka ho'ohana 'ana i ka vacuum ha'aha'a ha'aha'a e hana ana i nā huahana, he mea kūpono ke apono i ka mahana kokoke i ka palena ha'aha'a.I ka hana ʻana i nā huahana kikoo hohonu me ke ʻano paʻakikī, kūpono ke ʻae ʻana i ka mahana kokoke i ka palena kiʻekiʻe.ʻO ka maʻamau, ʻae ʻia ka mahana maʻamau.

Loaʻa iā mākou ka nui o nā lens Arylic, inā makemake ʻoe iā lākou, e ʻoluʻolu e kelepona mai iā mākou, hiki iā mākou ke hana i ka lens Arylic e like me kāu koi.Hiki iā ʻoe ke hoʻouna i ke kaha kiʻi iā mākou, a laila, hiki iā mākou ke hana i nā mold no ʻoe.Mahalo nui loa.